Pure porcelain Emax crown for highly aesthetic implants

Contemporary dentistry continually seeks solutions that combine the highest functional performance with unparalleled aesthetics, especially in dental implant rehabilitations. In this context, Pure Emax crowns emerge as the material of choice for cases demanding maximum naturalness and seamless integration with the patient’s smile.

Unlike other materials, Pure Emax, a type of lithium disilicate, offers a translucency and opalescence that perfectly mimic natural tooth structure, making it the ideal choice for crowns over implants in highly aesthetic areas. It’s important to highlight that these cutting-edge solutions are crafted in Brazil, reflecting our Clinic’s commitment to excellence in dental technology and artistry. Discover how this advanced technology, with its roots in Brazil, is revolutionizing dentistry, providing results that exceed expectations and restore confidence and beauty to smiles.

Contents

The digital all-porcelain crown is a highly efficient ceramic system used to make prosthetic crowns for dental implants.

What are digital pure porcelain crowns made of?

Lithium disilicate ceramics have aesthetic and resistance properties comparable to natural teeth. They are the best and most technologically advanced materials for achieving aesthetic teeth because they are white and translucent, which makes the crown look natural even in the brightest of environments.

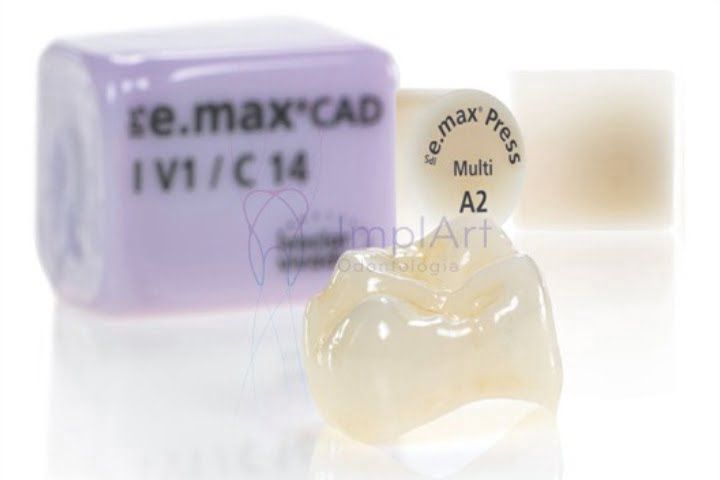

e.max ceramic was developed for use in Digital Dentistry Systems, with a 3D printer that sculpts dental prostheses. With this system, the all-porcelain crown can be made quickly, with more strength and naturalness than other materials made by hand.

What is the best material for pure porcelain digital prostheses?

The digital porcelain crown is made as a monoblock, i.e. it has no internal reinforcement layers, as the computer will create the crown from a prefabricated block of dental porcelain.

The Pura Digital porcelain crown is an evolution in the materials used in dental prostheses. With it, it is possible to reproduce details that make the prosthesis similar to natural teeth. With the Cerec System, the e.max crown is made more quickly and precisely, because it is designed on a computer and sculpted by robots.

The main advantages of modern porcelain crowns:

- High resistance todental fracture and durability;

- Very aesthetic look, comparable to a natural tooth;

- Range of blocks with different colors and types of resistance for different uses;

- Stain-resistant material;

- It can be made using the Metal Free technique (no metal in the internal structure). This makes the crown look translucent and much more aesthetic in bright environments.

- It can be designed and built quickly thanks to the Cerec system.

To make digitalpure porcelain crowns , we use CAD/CAM techniques:

1 – Intraoral scanner: It all starts with the digital molding of the dental implant with a high-precision color camera that takes images of the oral interior and sends them to the computer.

2 – Computer and software: receives the information captured by the intraoral scanner and carries out the simulation and personalized planning of the dental crown using three-dimensional images.

3 – Machine manufacturing: robots mill the e.max ceramic block based on the computerized design until the shape of the crown is achieved. The result is certainly a piece that is strictly compatible with the patient’s needs.

It is common for a temporary crown to be made before finalizing the permanent tooth to test whether the computer modeling is correct. Immediately after milling, the piece undergoes a crystallization process at approximately 850°C for 20 to 30 minutes and acquires high resistance, shade and translucency.

When the crown is finished, it is attached to the previously installed dental implant. For your convenience, the Cerec System and e.max ceramics are available at ImplArt Dental Clinic in Brazil. As an alternative to the pure porcelain crown, we now have an even more resistant material, translucent pure zirconia.

If you have any questions about this or other techniques and prices, please make an appointment or contact us. We are located in the Paulista Avenue area/Downtown of São Paulo. We will be happy to assist you.

Agende sua consulta agora por WhatsApp

Agende sua consulta agora por WhatsApp

Leave a Reply